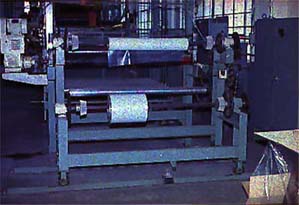

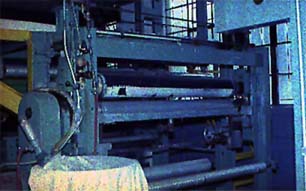

Satesa's single drum laminator/embosser is capable of performing

film to film (including metalized) fabric to fabric and film to

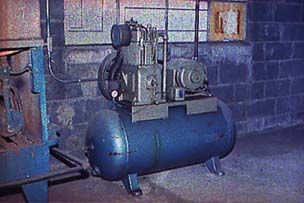

fabric as well as simultaneous embossing. The main head consists of a heat drum, embosser and cooling unit. The adhesive coated film is delivered for combining to a 36" diameter hot rolled steel drum which has a 64" chromed face. The combined mass is brought up to temperature by passing over three teflon coated boost cans and stripped for embossing prior to cooling. The aforementioned off-line technique permits maximum scheduling flexibility. Moreover, printing and top coating can be intergrated with this system to produce pleasing decorative effects.  The embossing section has a self-contained hydraulic system which ensures even travel and application of pressure across the face of the embossing roll. The hydraulic cylinders have sufficient stroke to clear the embossing roll for easy removal. Precision turn screws allow the operator to adjust the running stroke, too. The entire embossing section is mounted on heavy duty slides to facilitate embossing (backup) roll changes and maintenance.  The cooling section consists of two nominal 24" diameter chromeplated cooling drums. Each drum is jacketed for maximum cooling efficiency. The balance of the system consists of an adhesive coater, dual staggered unwinds (one with J box), slitter, two accumu- lators and winder.  The dual staggered unwinds allow the positioning of two rolls on its frame, on for running and one for ready-to-splice. Each unwind spindle has a manual tension brake with automotvie type lining to ensure smooth tensioning. Side lay adjusters are provided at each unwind station to allow side positioning of each roll. The unwind spindle is 1.25" square and one bar is supplied for each station. Light weight ribbed aluminum cones lock firmly on the spindle to secure 3" paper cores. In addition, the fabric unwind has the possibility of feeding a J box to further compensatory adjustments.   Two accumulators, one for film unwinding and one for product take-up, permit 40 yard capacity each for continuous operation during roll changes. The moving carriage has a bottom member with seven idlers and a top stationary section with eight idlers. All idlers have free bearings to minimize drag on the web. Tension in the unit can be altered by adjusting the state of balance with weights. The moving carriage rides on hardened and ground steel shafts with ball bearing followers.  The adhesive coater applies a coating of adhesive to the traveling web by means of a rotogravure process using an engraved roll for the applicator (supplied 80 line appli- cator).  The slitter has a hardened, sleeve type, slitter bar which allows removal of damaged or worn sleeves. The slitter also has air actuated circular slitter knives which can be adjusted by precision screws while running.  The winder is a dual type, constant tension unit with a timed-in core speed centerwinder. Quick transfer of cores is accomplished through tow core positions. The timed-in speed permits smooth starts and constant speed and tension through-out build up. This eliminates necking and drawing of material during starts, providing smooth uniform rolls. Core holders are supplied for winding 3" paper cores.  The drive system is through a variable frequency alternator. All the line drives are variable speed units and can be adjusted independently, enabling the line operator to correct and compensate for tension on different substrates. The system allows for the triming of individual stations while permitting synchronomous speeding and slowing of the entire line. The above line comes with a Dunham-Bush, 20 ton chiller which feeds the cooling cans and a Malsbary steam generator which supplies the heat drum and boost cans in exceptionally short time with steam. An air compressor and full support electrical panels and control station complete the offering. Any and all mixers and parts will be shipped, too.     Click Here for technical information |